Get Free Supplier Match Now

Just tell us what you need. We’ll find the right Japanese manufacturer for you.

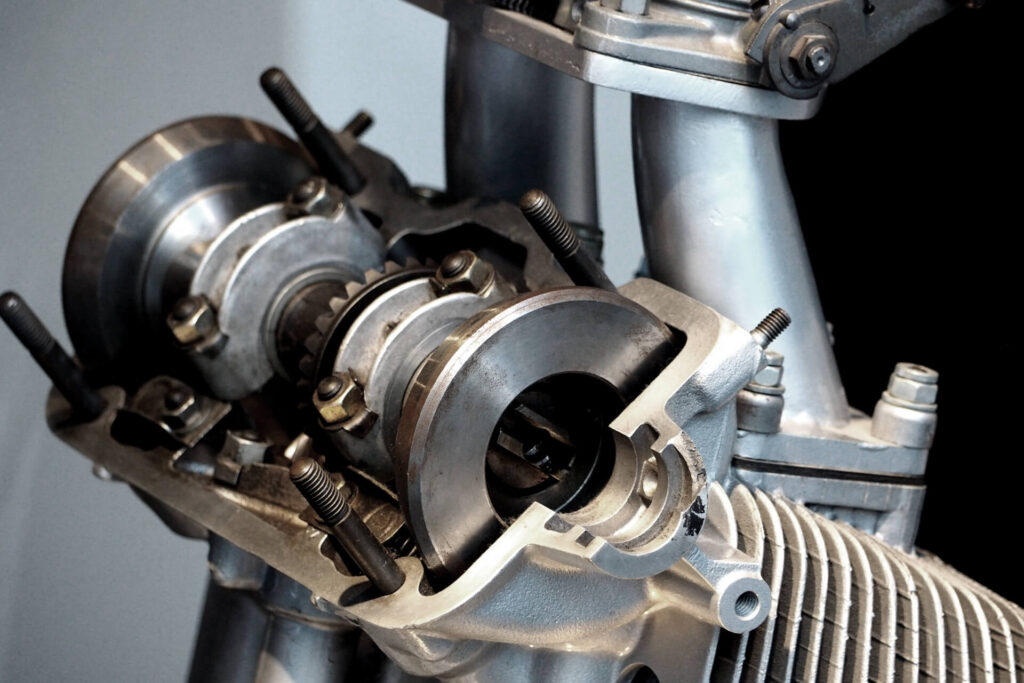

Japan is renowned for its excellence in precision manufacturing, particularly in industries such as automotive, electronics, aerospace, and machinery. When it comes to OEM parts Japan, the nation stands out for its unparalleled quality and technological prowess. However, international buyers often face unique challenges when trying to source OEM parts directly from Japan, including navigating language barriers, cultural nuances, and the fact that many of Japan’s top-tier small and mid-sized manufacturers (SMEs) are not widely visible on global platforms.

This step-by-step guide will provide you with a comprehensive roadmap, helping you navigate the OEM parts sourcing process from Japan, from initial planning to successful order placement.

Step 1: Precisely Define Your OEM Part Requirements

Effective sourcing OEM parts from Japan begins with absolute clarity. Japanese manufacturers prioritize precision and adherence to specifications.

What to include: Clearly outline your part specifications, including materials, dimensions, tolerances, surface finishes, quantity (including potential future volumes), strict deadlines, and the intended usage environment. For complex OEM components Japan, providing 2D/3D CAD files (e.g., STEP, IGES, DXF) and technical drawings is highly recommended.

Why it matters for Japan: Detailed requests are crucial. Japanese suppliers operate on meticulous standards; vague information can lead to significant miscommunication, delays, and inaccurate quotes. Precise details ensure faster, more accurate responses and help them assess their capabilities for your specific OEM components Japan.

How could defining your needs precisely lead to a smoother sourcing experience from Japan?

Step 2: Identify Suitable Japanese Suppliers & Navigating the Landscape

Finding the right Japanese manufacturers can be the most challenging yet crucial step in how to source parts from Japan.

Traditional Avenues: You can discover Japanese suppliers through major international trade shows (e.g., Hannover Messe, CES with Japanese exhibitors), specialized industry directories (though many are in Japanese), or some global online B2B platforms.

The SME Challenge: A key insight for direct sourcing Japan is that many of Japan’s most capable and technically advanced SMEs – the true backbone of its precision manufacturing – do not extensively advertise in English or appear on major global marketplaces. They often rely on domestic networks or specialized industry connections. This is where the challenge of sourcing OEM parts from Japan often arises.

Seeking Specialized Support: For how to source parts from Japan efficiently and access these hidden gems, leveraging a specialized service that understands both global buyer needs and the intricacies of the Japanese supply chain is vital.

Are you equipped to identify and connect with the best-fit Japanese suppliers for your specific OEM needs?

Step 3: Submit a Detailed RFQ (Request for Quotation) & Optimize Communication

Once you’ve defined your needs, the next step is the RFQ Japan process. This is your primary communication tool to convey your requirements to potential Japanese OEM suppliers.

Crafting your RFQ: Send a comprehensive Request for Quotation (RFQ) in clear, concise English. Include all specifications from Step 1. Remember, Japanese manufacturers value thoroughness.

Overcoming Communication Barriers: One common hurdle when sourcing OEM parts from Japan is the language barrier. While many engineers can read technical English, direct spoken communication might be challenging.

Streamlining with JapaneseMFG: This is where JapaneseMFG significantly simplifies your OEM parts sourcing journey. We support this critical process by collecting your detailed request, ensuring accurate translation (if needed), and leveraging our deep network to introduce you to pre-vetted Japanese suppliers who perfectly match your unique OEM components Japan needs and capabilities. This approach is designed to streamline your RFQ Japan submissions and ensure you connect with the right partners.

How can a well-prepared RFQ and optimized communication accelerate your sourcing timeline with Japanese manufacturers?

Step 4: Review Quotes, Evaluate, and Engage with Japanese Suppliers

Once you receive quotes, the evaluation phase begins. Remember that cost is just one factor.

Holistic Evaluation: Evaluate quotes not only by cost-effectiveness but also by lead time, proposed solutions, the quality of initial communication, and the supplier’s track record for reliability and quality assurance. Japanese suppliers might not aggressively negotiate on price compared to some other regions, as their pricing often reflects meticulous quality control and advanced processes. While the unit price for OEM parts Japan might sometimes appear higher, consider the total cost of ownership (TCO). This often includes significantly reduced defect rates, longer product lifespan, and fewer recalls, leading to substantial long-term savings.

Communication Nuances: Japanese manufacturers deeply value clear, professional, and consistent communication. They prioritize mutual trust and a collaborative approach over aggressive bargaining. Be prepared for detailed technical discussions and appreciate their thoroughness.

Beyond the initial quote, what long-term value are you truly seeking from a Japanese OEM partner?

Step 5: Finalize Order, Ensure Delivery & Inspection, and Foster Long-Term Partnerships

Upon selecting your preferred Japanese OEM supplier, meticulous finalization and diligent follow-through are key to success.

Confirming Terms: Clearly confirm all terms, including payment methods, Incoterms (logistics and shipping responsibilities), final delivery timelines, quality inspection protocols, and intellectual property (IP) protection agreements. Japanese manufacturers are particularly diligent about IP.

Delivery and Rigorous Inspection: Once the products are manufactured and delivered to the specified location within the agreed timeline, it’s crucial to conduct a thorough inspection in accordance with your contract. While Japanese suppliers are committed to high quality, a final verification is essential. Confirm appearance, dimensions, and functionality against agreed-upon quality standards and testing methods. If any issues arise, engage promptly and professionally with your supplier to find a resolution.

Building Relationships: Japanese manufacturers tend to prioritize long-term relationships based on consistent, professional interaction and mutual respect. Good communication post-delivery and sharing feedback can lead to smoother future transactions, enhanced support, and even access to future innovations.

Are you ready to build a lasting, high-value partnership with a Japanese OEM supplier?

Conclusion: Unlocking High-Quality OEM Sourcing from Japan

Sourcing OEM parts from Japan is an immensely rewarding endeavor when approached with the right process and understanding. By using a JapaneseMFG, fostering clear communication, and tapping into a network of trusted Japanese manufacturers, international buyers can gain unparalleled access to high-quality, precision manufacturing with reduced risk and greater transparency. The investment in these partnerships often yields superior product performance and a strong competitive edge.

Are you ready to unlock the potential of Japanese “Monozukuri” for your OEM needs?

Let JapaneseMFG be your bridge to success. We help connect you with the right precision parts supplier from Japan’s hidden gems – learn more or submit your request today and start your journey towards superior OEM components Japan.