Get Free Supplier Match Now

Just tell us what you need. We’ll find the right Japanese manufacturer for you.

Source high-quality plastic and resin parts from Japan with JapaneseMFG. Connect with trusted Japanese manufacturers specializing in custom injection molding, precision resin components, and ISO-certified production for medical, automotive, and electronics applications.

Introduction: Why Japanese Plastic & Resin Parts?

Sourcing high-quality plastic and resin components for global industries can be challenging. International buyers often face inconsistent quality, delayed deliveries, or suppliers lacking the technical expertise required for complex applications. Japan is internationally recognized for its precision manufacturing, advanced polymer knowledge, and strict quality standards, making it a reliable choice for sourcing high-performance plastic and resin components.

Through JapaneseMFG, buyers gain access to a curated network of Japanese manufacturers capable of delivering components that meet demanding specifications across automotive, medical devices, electronics, aerospace, and consumer goods. Partnering with JapaneseMFG ensures both performance and reliability, reducing risks commonly associated with international sourcing.

Unmatched Precision and Advanced Material Expertise

Japanese manufacturers excel in producing components with extremely tight tolerances and precise dimensions. Micro injection molding Japan, thin-wall plastic parts, and precision mold manufacturing in Japan are well-established specialties, enabling sub-millimeter accuracy essential for medical devices, aerospace applications, and advanced electronics. Even intricate, high-precision parts can be reliably produced, minimizing defects and ensuring consistent performance.

Beyond conventional plastics, Japanese suppliers have extensive experience with high-performance polymers, engineering plastics, and specialty resins such as PEEK, LCP, and PTFE. These materials are critical for applications requiring high heat resistance, chemical inertness, or durability under mechanical stress. JapaneseMFG facilitates connections with manufacturers who can advise on optimal material selection, ensuring your components perform reliably in challenging environments.

Cutting-Edge Manufacturing and Specialized Techniques

Japan’s plastic and resin industry offers a comprehensive suite of manufacturing technologies. Precision injection molding enables high-volume production with consistent repeatability, while blow molding allows lightweight, hollow components for complex designs. Thermoforming and vacuum forming accommodate larger or uniquely shaped parts, and 3D printing/additive manufacturing supports rapid prototyping or low-volume production of specialized resin components.

In addition, Japanese manufacturers are skilled in insert molding, overmolding, and two-shot injection molding, combining different materials or integrating metal and plastic components. These techniques reduce assembly steps, enhance part strength, and improve sealing performance, giving products a competitive advantage in the global market.

Flexible Quality Assurance Aligned to Your Needs

Quality control in Japan is a core aspect of manufacturing culture. Suppliers implement multi-stage inspections, Statistical Process Control (SPC), and adhere to international certifications such as ISO 9001, ISO 13485, and IATF 16949. JapaneseMFG allows buyers to select manufacturers whose quality assurance systems align with their project requirements, ensuring consistent batch quality while minimizing risk. This flexibility is especially valuable for medical devices, automotive components, and electronics where reliability is critical.

Applications Across Key Industries

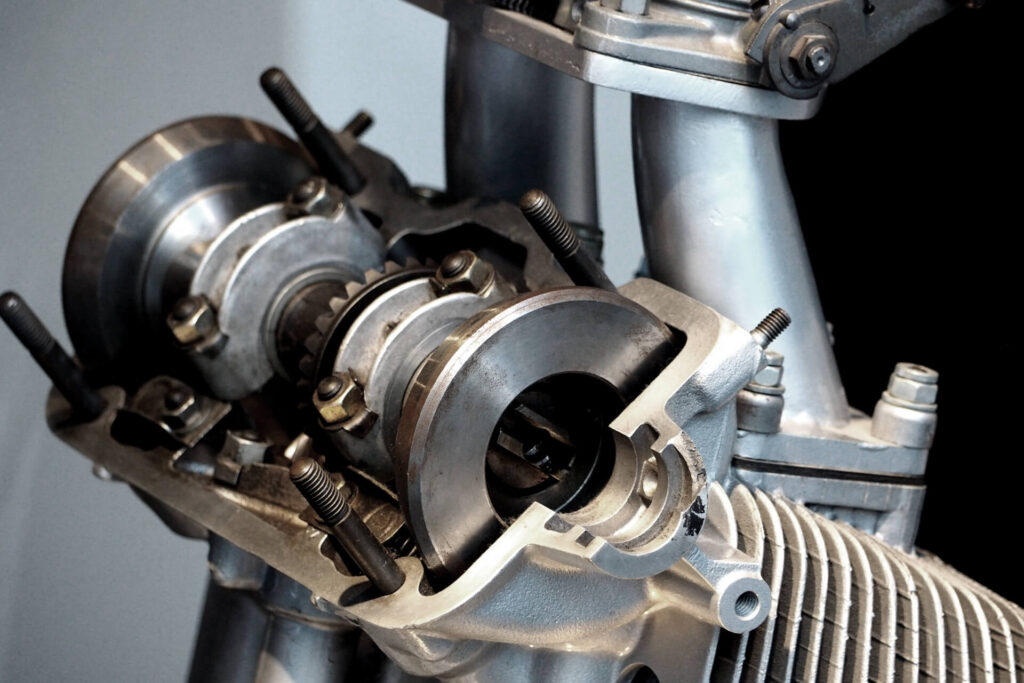

The high performance and reliability of Japanese plastic and resin parts make them indispensable in a wide range of sectors. In automotive applications, lightweight interior components, engine parts capable of withstanding high temperatures, and sensor housings are produced with precision. Medical device manufacturers rely on biocompatible disposable instruments, surgical tool parts, and diagnostic housings designed for sterilization resistance. Electronics benefit from high-durability casings, precision connectors, and semiconductor components. Aerospace and defense sectors demand lightweight yet strong structural parts capable of withstanding extreme environments, while industrial machinery and consumer goods rely on durable, chemically resistant components.

Streamlined Sourcing with JapaneseMFG

Navigating international supply chains can be complex. JapaneseMFG simplifies the process by connecting buyers with manufacturers experienced in plastic and resin component production. The platform bridges language and cultural barriers, provides support in technical specifications, facilitates negotiation, and manages end-to-end project coordination. Logistics and export guidance ensure components are delivered smoothly to global destinations.

By leveraging JapaneseMFG, buyers can quickly identify suitable manufacturers for custom plastic injection molding, high-performance resin parts, and specialized fabrication projects. The platform enables efficient comparison of multiple suppliers’ capabilities, timelines, and quotations, reducing time-to-market and ensuring confidence in product quality.

Conclusion: Elevate Your Products with Japanese Precision

Choosing Japanese plastic and resin manufacturers through JapaneseMFG guarantees components with exceptional precision, reliability, and material performance. Whether developing advanced medical devices, automotive parts, or high-tech electronics, partnering with Japanese suppliers ensures your products meet global standards and market expectations.

Contact JapaneseMFG today to discover your ideal Japanese manufacturing partner and experience the unmatched quality, expertise, and innovation that Japan offers in plastic and resin components.